Introduction

In the world of electronic and mechanical systems, hermetic feedthroughs play a crucial role in maintaining the integrity and reliability of operations. These feedthroughs are used to pass electrical signals, fluids, gases, or other media from a hermetically sealed environment to an external environment without compromising the containment of the sealed chamber.

What is a Hermetic Feedthrough?

A hermetic feedthrough is a device that allows for the transmission of signals, energy, or substances through a sealed barrier. This barrier is essential for protecting sensitive components from environmental factors such as moisture, dust, and other contaminants. By using a hermetic feedthrough, manufacturers can ensure the longevity and performance of their products in challenging conditions.

Why is Hermetic Feedthrough Testing Important?

Ensuring the quality and leak-proof performance of hermetic feedthroughs is critical for the success of any electronic or mechanical system. Without proper testing, manufacturers run the risk of product failure, which can lead to costly repairs, downtime, and even safety hazards. By conducting thorough testing procedures, companies can identify any potential leaks or defects early in the production process, saving time and resources in the long run.

The Testing Process

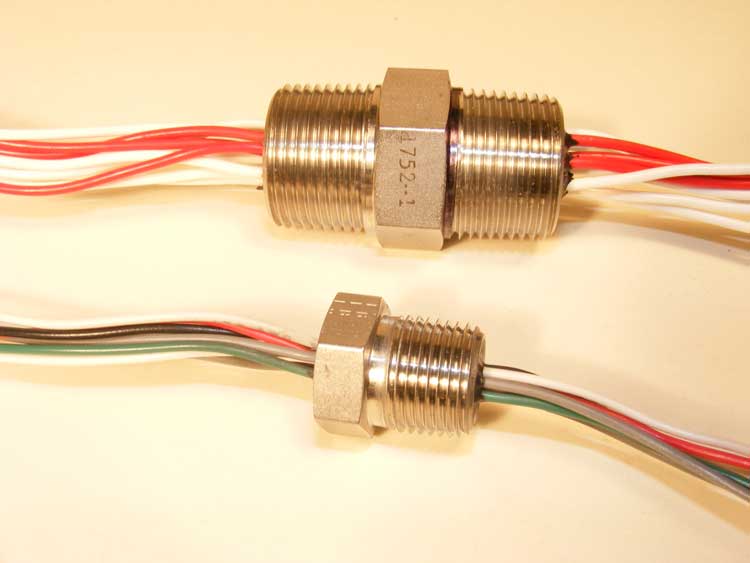

Visual Inspection

The first step in testing a hermetic feedthrough is to visually inspect the component for any visible defects or irregularities. This includes checking for cracks, scratches, or other imperfections that could compromise the seal of the feedthrough. By catching these issues early on, manufacturers can prevent further damage to the component and ensure its reliability.

Helium Leak Testing

Helium leak testing is a commonly used method for detecting even the tiniest leaks in hermetic feedthroughs. This non-destructive testing technique involves pressurizing the feedthrough with helium gas and then using a mass spectrometer to detect any traces of helium that may have escaped through a leak. By using helium as a tracer gas, manufacturers can pinpoint the exact location of the leak and take corrective measures to seal it properly.

Electrical Testing

In addition to leak testing, hermetic feedthroughs must also undergo electrical testing to ensure proper signal transmission. This involves passing a current through the feedthrough and measuring key parameters such as resistance, capacitance, and insulation resistance. By testing the electrical integrity of the feedthrough, manufacturers can guarantee that it performs as expected under operational conditions.

Mechanical Stress Testing

To simulate real-world conditions, hermetic feedthroughs are subjected to mechanical stress testing to assess their durability and reliability. This involves applying mechanical pressure, vibration, and temperature fluctuations to the feedthrough to evaluate its performance under different environmental conditions. By testing the feedthrough’s ability to withstand these stressors, manufacturers can identify any weaknesses and make necessary improvements.

Final Inspection

After completing all testing procedures, a final inspection is conducted to ensure that the hermetic feedthrough meets the required quality standards. This includes checking for proper sealing, electrical continuity, and overall functionality. Any deviations from the specifications are addressed, and the feedthrough is either approved for use or rejected for further analysis and correction.

Conclusion

In conclusion, hermetic feedthrough testing is a critical aspect of ensuring the quality and leak-proof performance of electronic and mechanical systems. By following a comprehensive testing process that includes visual inspection, helium leak testing, electrical testing, mechanical stress testing, and final inspection, manufacturers can guarantee the reliability and integrity of their products. Investing in proper testing procedures not only helps to prevent costly failures but also demonstrates a commitment to delivering high-quality products to customers.